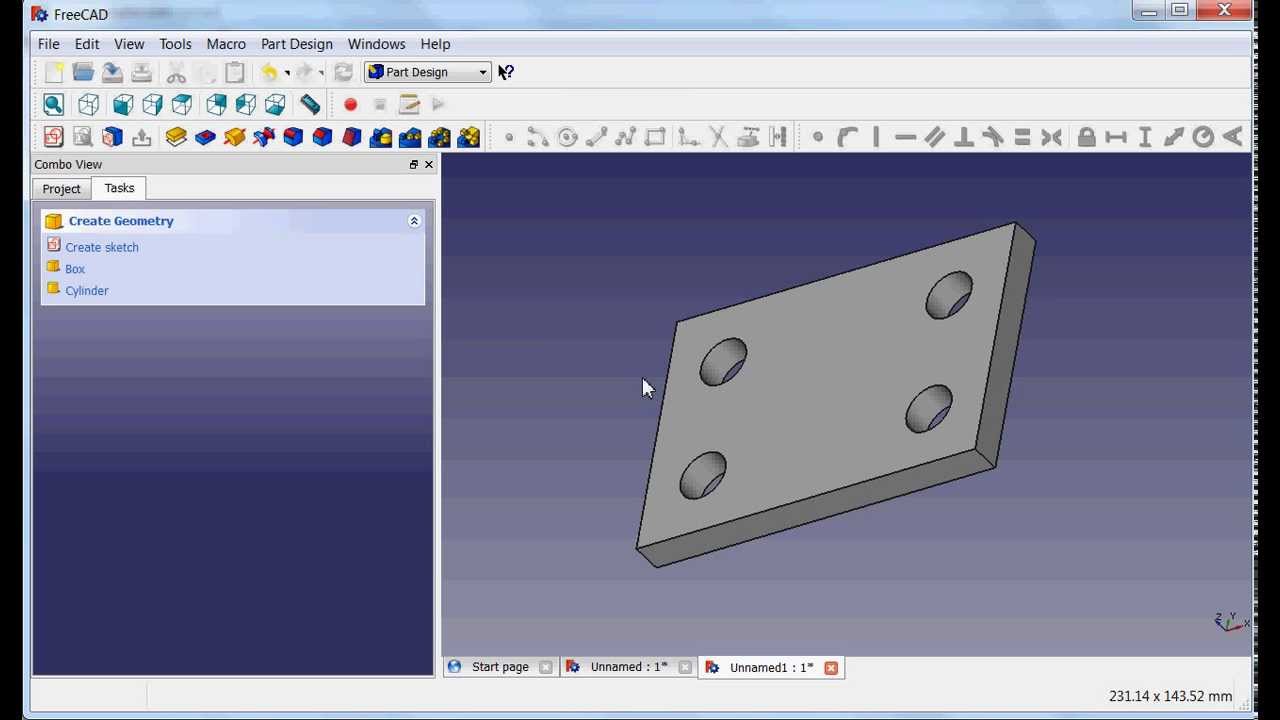

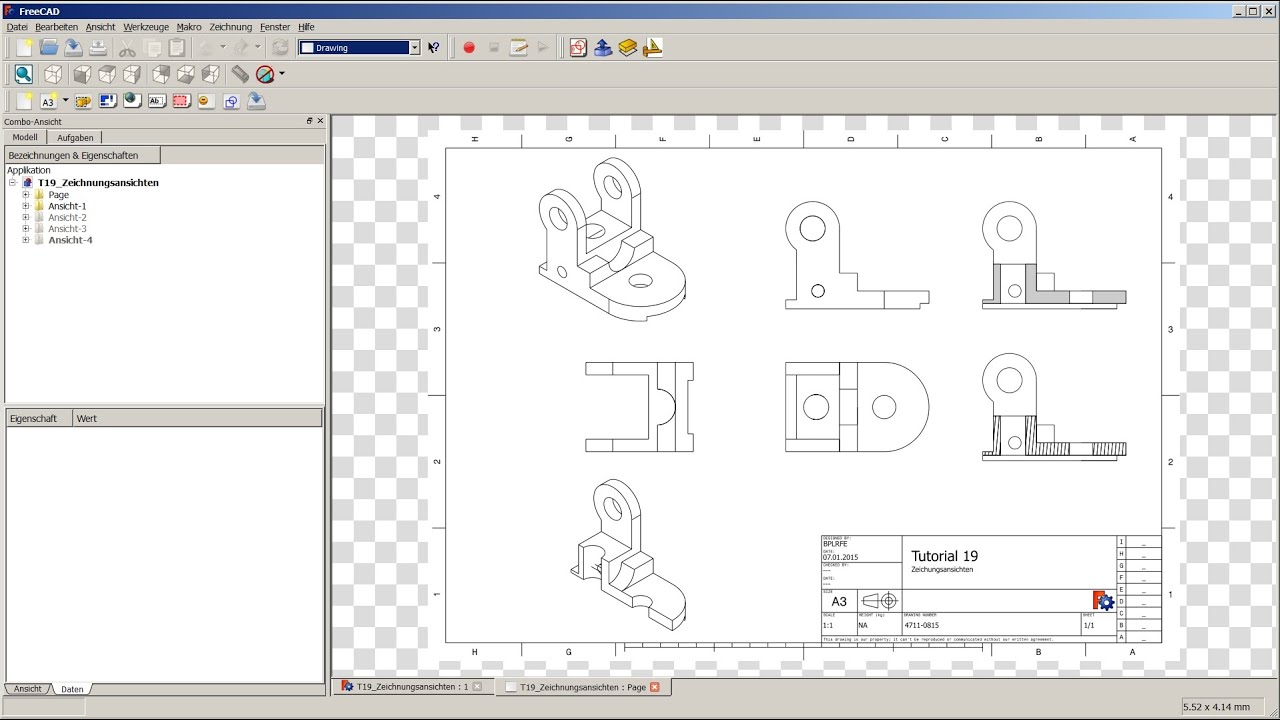

Indeed, it will help limiting the amount of material used, and thereby limit the cost of production. Hollow out a model is a common task in modeling for 3D printing. The solution to that issue is to use other parts (for example a cube rather than a matrix) The subtraction of one to another makes a weird result, which is not exportable in. Here, it’s called FusionįreeCAD is still under development, some features are still imperfect and Sometimes the Opencascade core on which turns freeCAD has trouble managing certain Boolean operations.įor example, a circular repetition patterns and a box: The new part is called by the operation name. Using the fusion function, the two parts merge into one new part. Then to apply one of the following Boolean operations : For 3D printing application, the Boolean operations between two (or many) shapes will permit you to get one whole part.įor that you just need to select two shapes : To select it, go to the tab part > Boolean operations, otherwise just right click on the concerned part in the arborescence. You can apply Boolean operations among all the created parts. These operations can be used at any time of the modelling, even it’s easier and more logical to use it progressively. It’s appropriate to create a part for each operation, in the aim to be able to make specific modifications on certain parts, with for example the Boolean operations. To modify these geometries you have access to many tools like Boolean operations, fusion, common, cuts operations. The volume modelling is used for simple geometries ( primitive objects like cone, box, cylinder…).

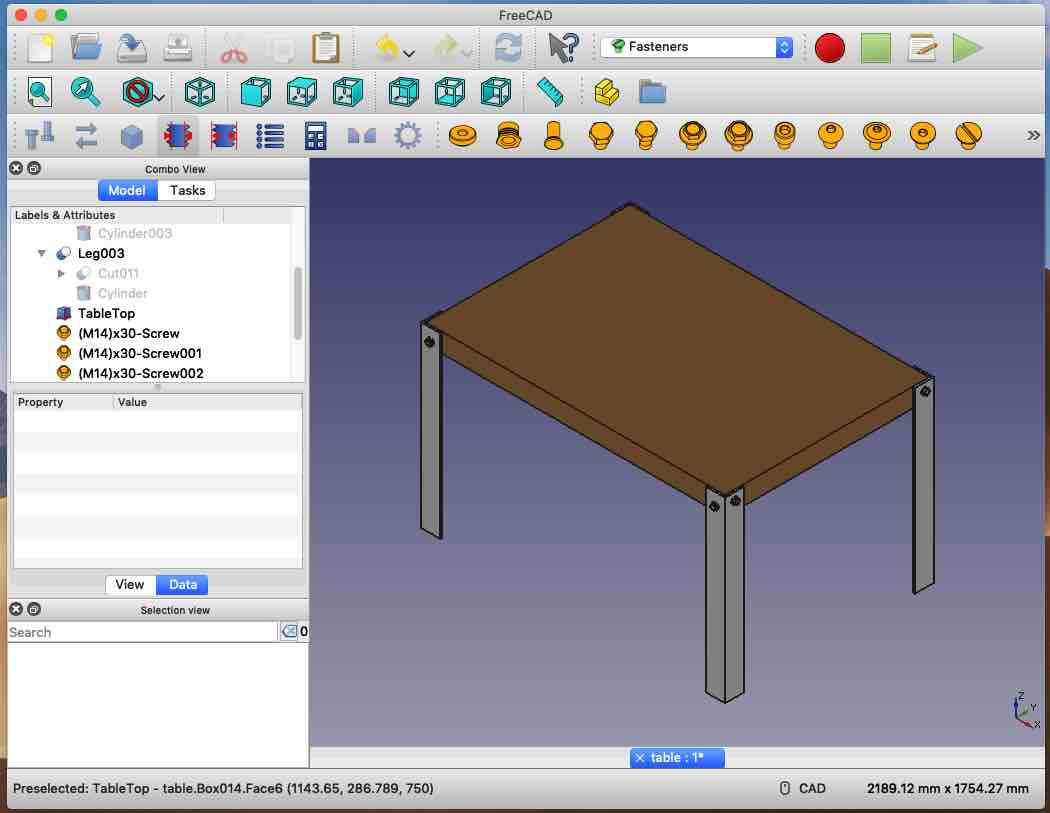

It’s possible to export different parts in one. We invite you to consult our page on materials. In that way, you have to keep in mind the cantilever notions, the material thickness specifications, the minimum strength of materials of your part etc. Don’t forget that your file will become a real piece.We will detail export possibilities and the file weight in the chapter dedicated to the model export. This sizing is widely sufficient to generate a file without losing accuracy in the part. Your 3D file needs to be less than 50Mb after the export in.But we will see that Freecad manages that easily and automatically. Your part (object) must have an « inside» and an « outside».Freecad has no surface workbench, so this should not cause you problems. All the components you will design need to have a certain thickness.

The different elements of your modeling should not intersect.It’s important for the design to respect the following rules :

In this section, you will learn the key concepts of modeling with freeCAD for 3D printing. Indeed, beyond the own limits to the materials used, it is necessary to keep in mind that the resulting file will not only be a virtual representation, but a support for the 3D printer to create a physical object. Designing for 3D printing implies to respect some design rules.

0 kommentar(er)

0 kommentar(er)